Unlocking the Secrets of Base Material: Comprehensive Detection and Analysis

Overview: Why Base Material Detection Matters

The **base material** plays a critical role in ensuring the structural integrity and performance of products across industries like construction, manufacturing, and aerospace. Understanding its composition and properties through advanced detection methods helps ensure quality, compliance, and safety. In this article, we delve into the essential steps for detecting and analyzing base materials, providing a comprehensive guide to the process.

Sample Selection: The Starting Point for Accurate Detection

Proper **sample preparation** is the foundation of precise base material detection. Samples should be representative of the material’s bulk properties and free of contaminants. For instance:

- Metallic base materials: Ensure clean, rust-free surfaces.

- Composite materials: Verify uniformity in fiber and resin distribution.

- Ceramic materials: Avoid cracks or irregularities during sampling.

Detection Projects: Key Parameters for Base Material Analysis

The detection of base materials typically focuses on several critical parameters, including:

- Chemical Composition: Identifies the elemental makeup to determine material type and grade.

- Mechanical Properties: Evaluates tensile strength, hardness, and ductility.

- Microstructure: Reveals grain size, phase distribution, and potential defects.

- Thermal Properties: Assesses heat resistance and thermal expansion behavior.

- Surface Properties: Investigates coatings, oxidation, and surface roughness.

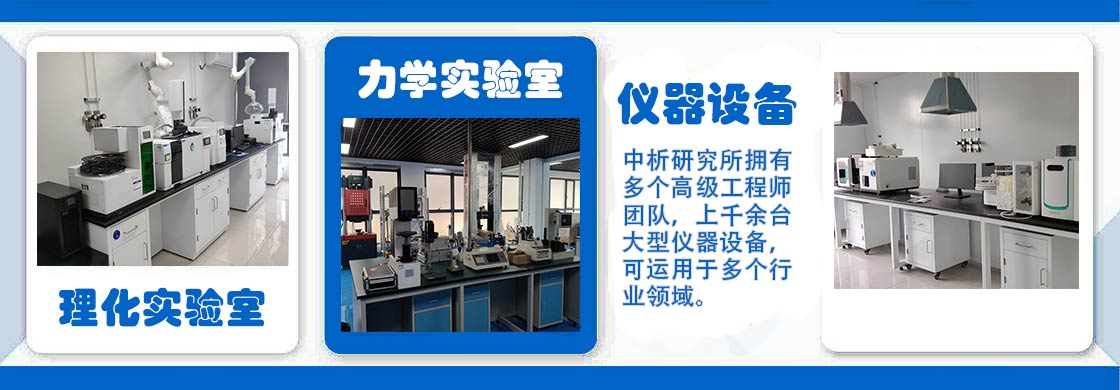

Detection Instruments: Tools for Precision Analysis

Modern detection relies on cutting-edge instrumentation. Commonly used tools include:

- Scanning Electron Microscopes (SEM): For high-resolution imaging of microstructures.

- Energy-Dispersive X-ray Spectroscopy (EDS): For chemical composition analysis.

- Universal Testing Machines (UTM): For mechanical property evaluation.

- Fourier Transform Infrared Spectrometers (FTIR): For detecting organic and polymeric materials.

- X-ray Diffraction (XRD): For phase and crystallinity analysis.

Detection Methods: From Sampling to Reporting

The process of detecting and analyzing base materials involves a series of precise steps:

- Sample Preparation: Cutting, polishing, or cleaning the material to achieve the desired state.

- Instrument Calibration: Ensuring equipment accuracy with standards.

- Testing: Performing targeted analyses, such as tensile tests or spectroscopic measurements.

- Data Interpretation: Analyzing results to assess material quality and identify any discrepancies.

- Reporting: Compiling findings into a detailed report for stakeholders.

Conclusion: Elevating Material Confidence Through Detection

Base material detection is a cornerstone of modern industry, providing the insights needed to optimize performance and ensure safety. By combining advanced instrumentation with systematic methodologies, manufacturers and researchers can uncover the hidden properties of materials, paving the way for innovation and excellence. Whether you’re an engineer or a quality control specialist, mastering the science of material detection is key to success in today’s competitive landscape.

结语

以上是关于Unlocking the Secrets of Base Material: Comprehensive Detection and Analysis的介绍,如有其它问题请 联系在线工程师 。

第三方检测机构

第三方检测机构

备案号:

备案号: