Comprehensive Transmission System Testing: Ensuring Performance and Reliability

Overview of Transmission System Testing

Transmission systems are the backbone of mechanical and automotive engineering, directly influencing the efficiency, safety, and durability of vehicles and machinery. Accurate and scientific testing is essential to ensure optimal performance and identify potential faults. This article explores the key aspects of transmission system testing, from sample requirements to advanced methodologies, providing a comprehensive guide for professionals and enthusiasts alike.

Transmission Testing Samples

For reliable testing, **sample selection** plays a crucial role. Typical samples include:

- Automotive Transmission Systems: Automatic, manual, and CVT systems for passenger and commercial vehicles.

- Industrial Gearboxes: Used in manufacturing and heavy equipment.

- Custom Components: Such as clutches, shafts, and bearings.

Key Transmission Testing Parameters

Transmission testing involves multiple parameters that reflect system performance and reliability, including:

- Torque and Power Transmission: Efficiency measurements under varying loads and speeds.

- Noise and Vibration: Detection of potential imbalances or defects in moving parts.

- Thermal Behavior: Heat generation and dissipation during operation.

- Lubrication Performance: Assessment of lubricant effectiveness under different conditions.

- Durability Tests: Long-term stress analysis to evaluate material and design robustness.

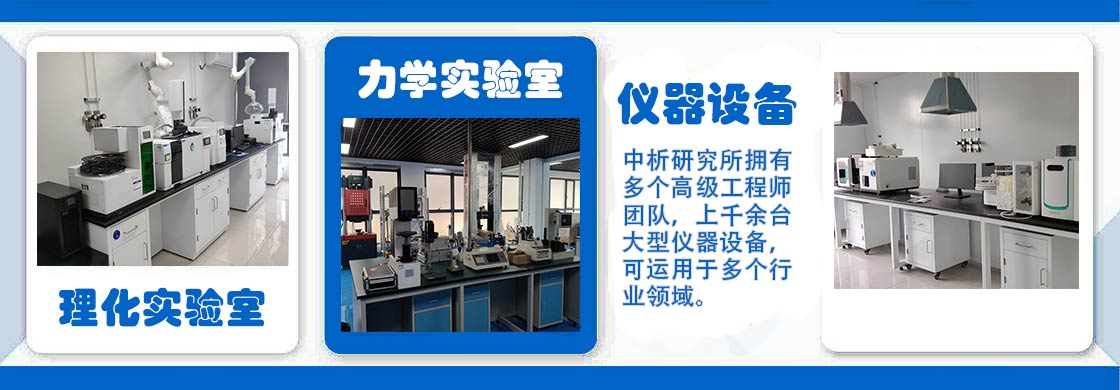

Testing Equipment and Instruments

Advanced testing requires high-precision instruments tailored to the demands of transmission systems. Commonly used equipment includes:

- Dynamometers: Measure torque, speed, and power output.

- Vibration Analyzers: Detect irregularities in rotating components.

- Thermal Imaging Cameras: Monitor heat patterns during operation.

- Endurance Test Rigs: Simulate prolonged usage conditions.

- Oil Analysis Tools: Evaluate lubrication properties and contamination levels.

Testing Methods and Techniques

The methodology adopted directly impacts the testing results. Widely applied methods include:

- Static Testing: Focused on stationary assessments of key properties like torque capacity.

- Dynamic Testing: Real-time evaluation under operational conditions, using dynamometers and test rigs.

- Non-Destructive Testing (NDT): Techniques like ultrasonic, X-ray, and magnetic particle inspection to check internal defects.

- Simulation-based Testing: Computer simulations for performance prediction and design validation.

Conclusion

Transmission system testing is a multifaceted process that requires a blend of expertise, precise equipment, and robust methodologies. By focusing on scientific accuracy and thorough evaluation, it is possible to ensure system reliability and enhance overall performance. Professionals involved in testing and development must stay updated with the latest techniques and tools to maintain high standards and innovation within the industry.

结语

以上是关于Comprehensive Transmission System Testing: Ensuring Performance and Reliability的介绍,如有其它问题请 联系在线工程师 。

第三方检测机构

第三方检测机构

备案号:

备案号: