Comprehensive Guide to Power Strip Testing: Ensuring Safety and Reliability

Overview: Why Testing Power Strips Is Crucial

Power strips are indispensable in modern homes and workplaces, providing multiple outlets for electrical devices. However, their safety and performance must not be overlooked, as faulty products can lead to fire hazards or equipment damage. **Rigorous testing ensures reliability**, compliance with standards, and user safety, making it essential for manufacturers, retailers, and consumers alike.

Testing Samples: What Needs to Be Examined?

Testing typically involves a variety of power strip types, including those with surge protection, USB ports, and smart functionalities. Samples are collected from different production batches to assess consistency. **Key factors like material durability, insulation quality, and circuit integrity** are prioritized during the sampling process to reflect real-world conditions.

Testing Items: Key Parameters to Evaluate

The primary testing projects for power strips include:

- Electrical Safety: Ensuring insulation resistance and grounding are adequate.

- Overload Protection: Testing the response to excessive power loads.

- Heat Resistance: Assessing performance under high-temperature conditions.

- Surge Protection: Measuring the ability to handle voltage spikes.

- Durability: Evaluating wear and tear resistance over time.

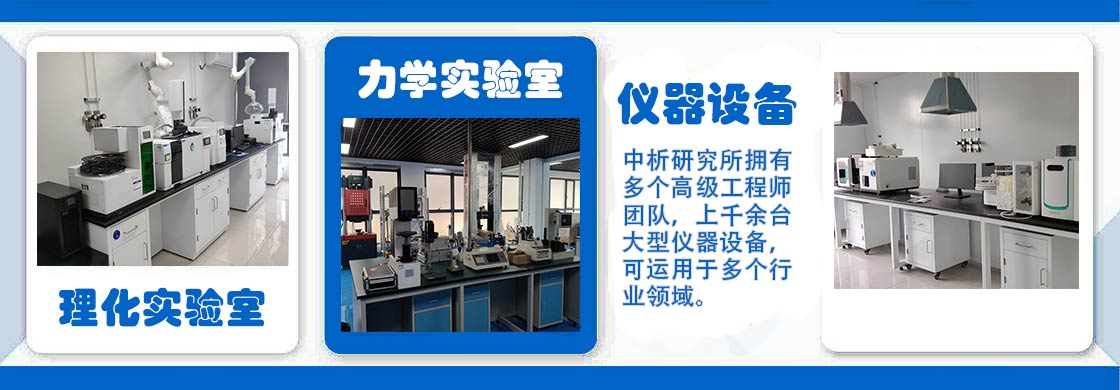

Testing Instruments: Advanced Tools for Accurate Results

Reliable testing requires specialized instruments, such as:

- Dielectric Voltage Testers: To measure insulation resistance and breakdown voltage.

- Thermal Analyzers: For monitoring heat dissipation and resistance under load.

- Surge Generators: To simulate voltage spikes and test surge protection capabilities.

- Multi-function Testers: Combining multiple tests like continuity, grounding, and resistance.

**Accurate testing tools ensure that results are consistent, repeatable, and compliant with international safety standards.**

Testing Methods: Step-by-Step Processes

The testing process for power strips follows stringent protocols:

- **Visual Inspection:** Assessing build quality, design, and labeling compliance.

- **Electrical Testing:** Measuring insulation, grounding continuity, and load capacity.

- **Overload Simulation:** Running the power strip at maximum rated load to check for trip mechanisms.

- **Environmental Tests:** Exposing the device to varying temperatures, humidity, and voltage conditions.

- **Endurance Testing:** Repeated plug-in and unplug cycles to evaluate mechanical durability.

**Following these steps guarantees that the product can withstand real-world conditions without compromising safety or performance.**

Conclusion: The Value of Rigorous Testing

Power strips are essential devices, yet their reliability hinges on thorough testing. From assessing electrical safety to verifying surge protection, each step ensures compliance with safety standards and user satisfaction. **By prioritizing comprehensive testing**, manufacturers and consumers alike can confidently depend on power strips to deliver performance and security in every application.

结语

以上是关于Comprehensive Guide to Power Strip Testing: Ensuring Safety and Reliability的介绍,如有其它问题请 联系在线工程师 。

第三方检测机构

第三方检测机构

备案号:

备案号: