Unlocking the Secrets of Antibacterial Panels: Comprehensive Testing Guide

Overview: Understanding the Importance of Antibacterial Panels

Antibacterial panels are increasingly used in healthcare, food processing, and home environments due to their ability to inhibit microbial growth. These innovative materials combine durability with hygiene, offering a practical solution to improve public health and sanitation. However, how can we ensure their effectiveness? This article delves into the comprehensive testing of antibacterial panels, providing insights into sample selection, testing methods, and the tools used for evaluation.

Sample Selection: Key Considerations for Testing

Accurate testing begins with representative **samples**. For antibacterial panels, the choice of samples depends on their intended application. For example, panels used in **hospitals** may be tested against a broader range of pathogens compared to panels for residential use. Samples should include varying **thicknesses, surface finishes**, and core materials to reflect real-world usage scenarios. The testing protocol also considers whether the panel has been treated with coatings or embedded antibacterial agents.

Testing Items: What Do We Evaluate?

To comprehensively evaluate an antibacterial panel, the following key **testing items** are typically included:

- **Antibacterial efficacy:** Measuring the reduction rate of bacteria such as Escherichia coli and Staphylococcus aureus.

- **Durability:** Assessing whether antibacterial properties persist after wear, cleaning, or prolonged use.

- **Surface properties:** Testing for resistance to scratches, stains, and chemical exposure.

- **Material safety:** Ensuring no harmful substances are released during usage.

Each of these parameters helps verify the panel’s performance and safety in its intended environment.

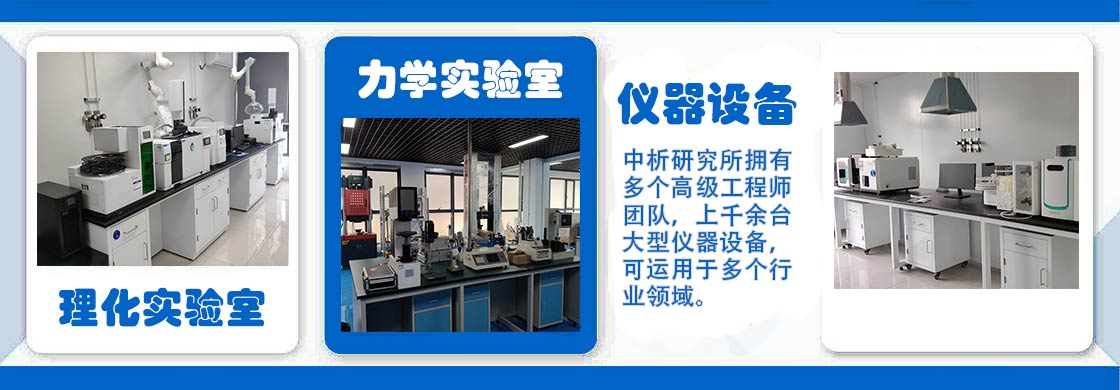

Testing Instruments: Advanced Tools for Precision

Reliable testing requires advanced instruments that meet international standards. Key instruments include:

- **Microbial incubators:** For cultivating and quantifying bacteria under controlled conditions.

- **Surface analysis tools:** Such as scanning electron microscopes (SEM) to assess surface integrity and antibacterial coatings.

- **Wear testers:** To simulate real-world wear and tear on the panels.

- **Spectrophotometers:** To detect chemical residues or changes in the panel's composition.

Using these tools ensures the accuracy and reproducibility of test results.

Testing Methods: Step-by-Step Protocols

Testing antibacterial panels involves standardized methods to ensure consistency. Commonly used protocols include:

- **JIS Z 2801 / ISO 22196:** Evaluates antibacterial activity on plastic and non-porous surfaces.

- **ASTM D4060:** Measures abrasion resistance of organic coatings.

- **Antimicrobial leaching tests:** Check for the release of active agents into the environment.

These methods often involve inoculating the panel surface with bacteria, incubating under controlled conditions, and analyzing bacterial reduction over a specific period.

Conclusion: Ensuring Safety and Performance

Testing antibacterial panels is an essential step in validating their effectiveness and ensuring they meet the highest standards of safety and performance. With rigorous protocols and state-of-the-art instruments, manufacturers can offer products that genuinely improve hygiene and public health. As demand for these materials grows, thorough testing will remain at the forefront of innovation and trust.

结语

以上是关于Unlocking the Secrets of Antibacterial Panels: Comprehensive Testing Guide的介绍,如有其它问题请 联系在线工程师 。

第三方检测机构

第三方检测机构

备案号:

备案号: