Unlocking the Mystery: Comprehensive Testing of Safes

Overview of Safe Testing

Safes are essential for securing valuable items, important documents, and personal belongings. However, not all safes are created equal. Comprehensive testing ensures they meet the required standards of durability, security, and functionality. This article delves into the critical aspects of safe testing to ensure your investment provides the protection you need.

Sample Selection for Testing

When testing safes, **sample selection** is a key step. Samples are chosen to represent various models and specifications available in the market. These include small personal safes, fireproof safes, and high-security safes used in commercial settings. Testing samples should be in their original condition without any prior modifications to ensure results reflect real-world performance.

Key Testing Parameters

Safe testing involves a series of evaluations under specific parameters to determine their effectiveness. The most common **testing items** include:

- Durability Testing: Assessing the safe's ability to withstand wear and environmental factors.

- Fire Resistance: Measuring performance under high-temperature conditions to ensure fireproof claims.

- Impact Resistance: Testing the safe's ability to survive drops or blunt force impacts.

- Security Features: Evaluating locks, anti-tamper mechanisms, and overall resistance to unauthorized access.

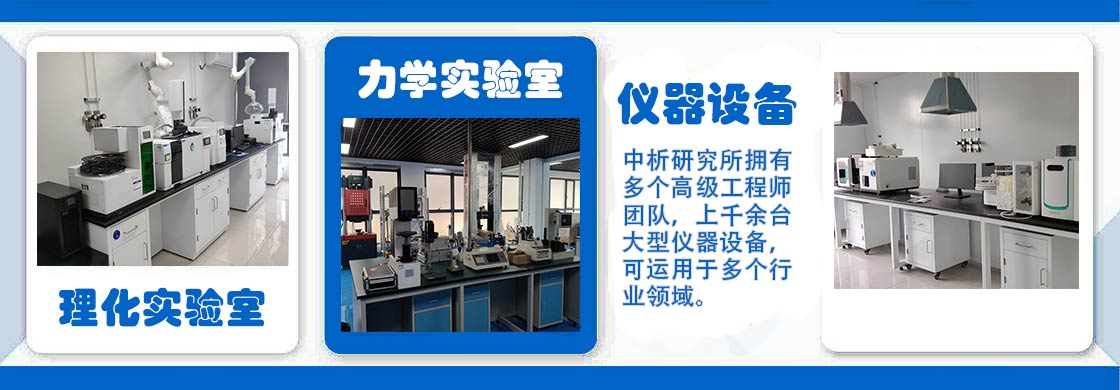

Testing Instruments and Equipment

Professional testing laboratories use **specialized instruments and equipment** to simulate various real-world scenarios. Common tools include:

- High-temperature furnaces for fire resistance testing.

- Impact hammers and drop towers for assessing structural integrity.

- Lock-picking devices to evaluate lock security.

- Advanced sensors to measure internal conditions during stress tests.

These instruments provide precise measurements to ensure the safes meet established safety standards.

Testing Methods and Standards

Safe testing is conducted using **scientifically rigorous methods** based on international standards such as UL, EN, or ISO. For example:

- Fire Resistance Tests: Safes are exposed to extreme heat for a specified duration to test material resilience.

- Break-in Simulations: Experts attempt to bypass the safe's security mechanisms using tools commonly used by intruders.

- Water Resistance Checks: Testing for water infiltration to ensure contents remain dry in floods or leaks.

These methods not only validate the manufacturer’s claims but also build consumer confidence in the product.

Conclusion

Testing safes is a multi-faceted process that examines their durability, security, and reliability under various conditions. By understanding the rigorous evaluation methods, consumers can make informed choices when purchasing a safe. Whether for personal or commercial use, thorough testing ensures that safes deliver the promised level of protection for your valuables.

结语

以上是关于Unlocking the Mystery: Comprehensive Testing of Safes的介绍,如有其它问题请 联系在线工程师 。

第三方检测机构

第三方检测机构

备案号:

备案号: